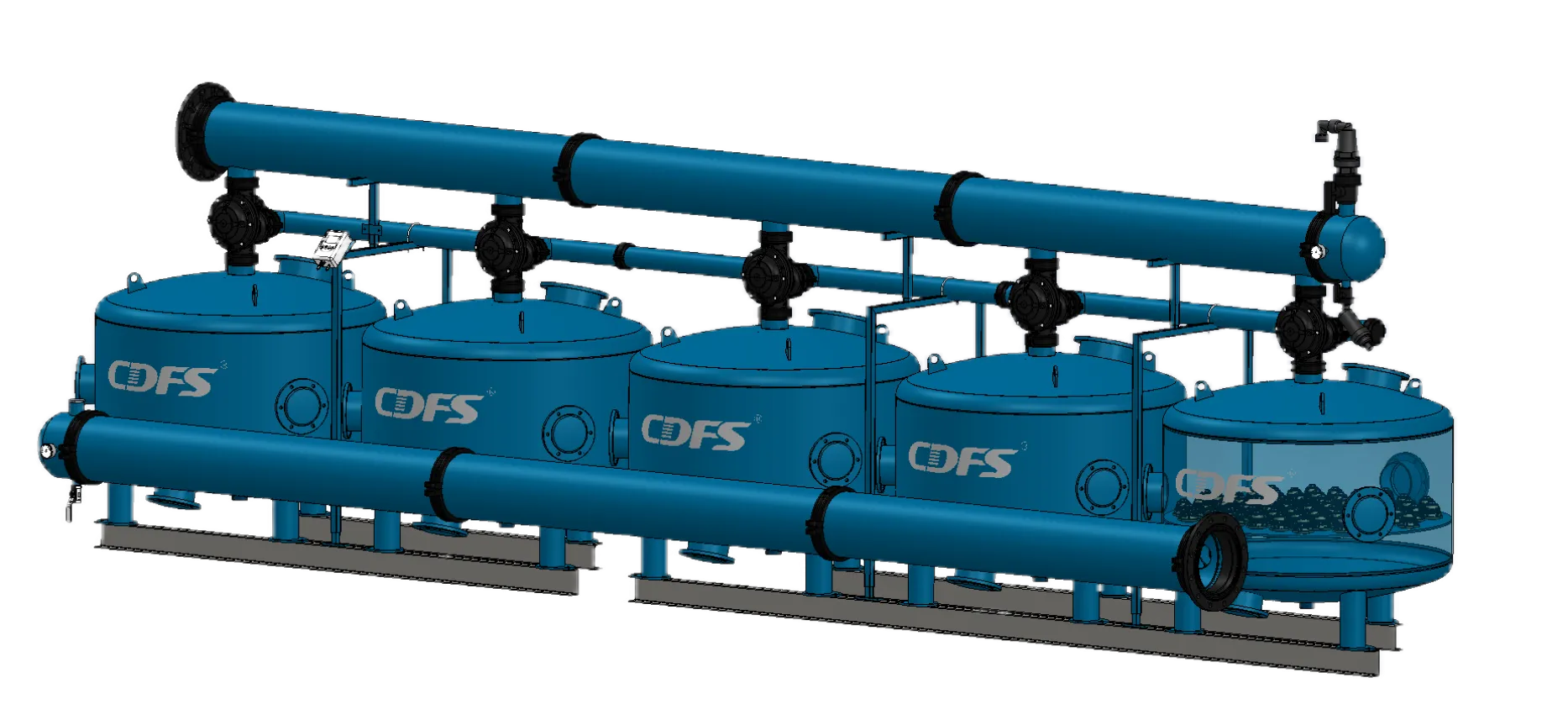

Automatic self-cleaning water filters: Single unit flow 19-2000m3/h Filtration precision 20-4000 micron

Type:Multi units Material:Carbon steel Cleaning:Backwashing Control:Automatic

Product advantages

> High flow rate/high filtration accuracy

> Low pressure loss/low backwash water consumption

> High automation level

Product principle

|

Sand Media Filters: A Key Player in Water Treatment Processes

Sand media filters are integral components in the water treatment industry, playing a crucial role in purifying and maintaining water quality. Their significance in various water treatment processes can be outlined as follows: 1. Removal of Suspended Particles: Sand media filters are highly effective in removing suspended particles from water. They work by allowing water to pass through layers of sand, which trap and remove particles, thus clarifying the water. 2. Versatility in Applications: These filters are versatile and can be used in a range of settings, from municipal water treatment plants to industrial and agricultural applications. They are particularly effective in treating groundwater, surface water, and wastewater. 3. Sustainable Water Treatment: Sand media filters are a sustainable option for water treatment. They require minimal maintenance and are energy-efficient, making them a cost-effective solution for long-term water purification. 4. Enhancing Water Quality: By removing contaminants and impurities, sand media filters significantly enhance the quality of water. This is essential for ensuring safe drinking water and for meeting the water quality standards required in various industrial processes. 5. Compatibility with Other Treatment Methods: These filters can be used in conjunction with other water treatment methods, such as chemical treatment and UV disinfection, to achieve comprehensive water purification.

How the Sand Media Filter Work? The Filtering Process

Filtering with media filters, also known as depth filtration, is done by filtering water through a thick layer of graded particles, called the filter bed. These particles can be sand, gravel or other granular materials. The filtration degree depends on the effective size of the bedding and the water velocity through the filter. The Cleaning Process |

|

| Product Advantages | ||||||||

| Core components brands(BERMAD、BACCARA、SIEMEN、MITSUBISHI). | ||||||||

| The design of filtration unit is single chamber which have better backwash effect and the probability is less that sand flow out. | ||||||||

| Utilizing stainless steel collector which have longer life. | ||||||||

| Water outlet is located in the bottom of vessel that is convenient for maintenance. |

| Product Features | ||||||||

| High speed flow and low pressure loss. | ||||||||

| Modular and compact design.(The area decreased by more than 40% and piping reduced by at least 50%). | ||||||||

| Manual, semi-automatic, full-automatic backwash optional. | ||||||||

| Back washing could choose filtering cleaning water or another water source, which is free to switch(when needed). | ||||||||

| 20"-56"vessels are combined to make flow expand freely. | ||||||||

| Carbon steel vessels and pipelines are anticorrosion processed through phosphate surface treatment and 240℃ high temperature electrostatic coating. |

| Model | Quantities of tank | Min flow rate (m3/h) |

Max flow rate (m3/h) |

Filtration area (m2) |

Backwash flow rate (m3/h) |

Max pressure (MPa) |

Water inlet/outlet | Drain outlet |

| DMF-2024-1A | 1 | 4 | 6 | 0.2 | 6 | 0.8 | 2" | 2" |

| DMF-2424-1A | 1 | 7 | 11 | 0.28 | 11 | 0.8 | 2" | 2" |

| DMF-2024-2A | 2 | 8 | 12 | 0.4 | 6 | 0.8 | 2" | 2" |

| DMF-2824-1A | 1 | 9.5 | 15 | 0.38 | 15 | 0.8 | 2" | 2" |

| DMF-2024-3A | 3 | 12 | 18 | 0.6 | 6 | 0.8 | 3" | 2" |

| DMF-2424-2A | 2 | 14 | 22 | 0.56 | 11 | 0.8 | 3" | 2" |

| DMF-3624-1A | 1 | 16 | 24 | 0.64 | 24 | 0.8 | 3" | 3" |

| DMF-2824-2A | 2 | 19 | 30 | 0.76 | 15 | 0.8 | 4" | 2" |

| DMF-2424-3A | 3 | 22 | 32 | 0.84 | 11 | 0.8 | 3" | 3" |

| DMF-4824-1A | 1 | 29 | 43 | 1.13 | 43 | 0.8 | 3" | 3" |

| DMF-3624-2A | 2 | 32 | 48 | 1.28 | 24 | 0.8 | 4" | 3" |

| DMF-2824-3A | 3 | 28.5 | 45 | 1.15 | 15 | 0.8 | 4" | 3" |

| DMF-5624-1A | 1 | 39 | 58 | 1.54 | 58 | 0.8 | 4" | 4" |

| DMF-3624-3A | 3 | 48 | 72 | 1.92 | 24 | 0.8 | 6" | 3" |

| DMF-4824-2A | 2 | 57 | 86 | 2.26 | 43 | 0.8 | 6" | 4" |

| DMF-5624-2A | 2 | 78 | 108 | 3.08 | 54 | 0.8 | 6" | 4" |

| DMF-4824-3A | 3 | 86 | 129 | 3.39 | 43 | 0.8 | 6" | 4" |

| DMF-5624-3A | 3 | 117 | 174 | 4.62 | 58 | 0.8 | 8" | 4" |

| DMF-4824-4A | 4 | 115 | 172 | 4.52 | 43 | 0.8 | 8" | 4" |

| DMF-4824-5A | 5 | 143 | 215 | 5.65 | 43 | 0.8 | 8" | 4" |

| DMF-4824-6A | 6 | 172 | 258 | 6.78 | 43 | 0.8 | 10" | 4" |

| DMF-5624-4A | 4 | 156 | 232 | 6.16 | 58 | 0.8 | 8" | 4" |

| DMF-5624-5A | 5 | 195 | 290 | 7.7 | 58 | 0.8 | 10" | 4" |

| DMF-5624-6A | 6 | 234 | 348 | 9.24 | 58 | 0.8 | 10" | 4" |